ニューロンドンのご紹介

ニューロンドンのご紹介

株式会社ニューロンドンは~

株式会社ニューロンドンは

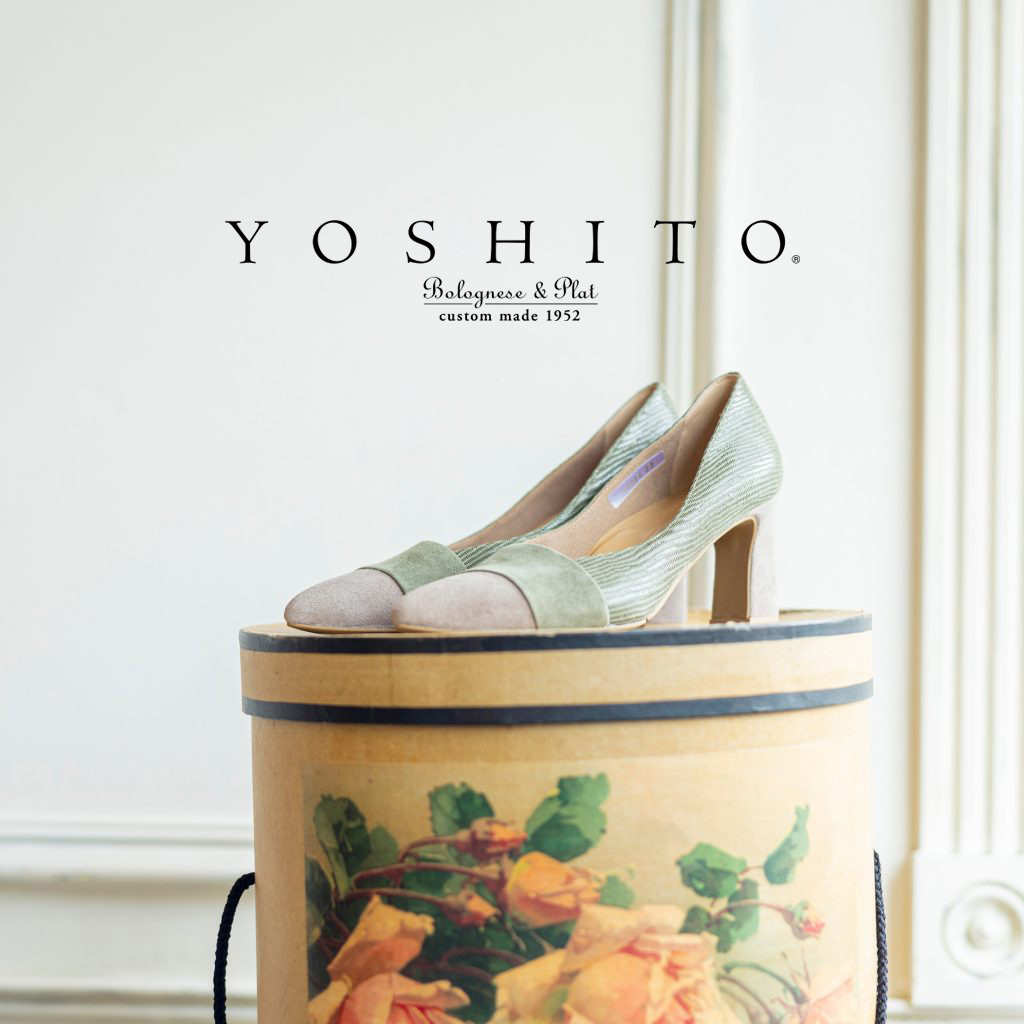

オリジナルシューズブランド”YOSHITO”を

製造・販売するシューズメーカーです。

「こだわりの製法」

「厳選した素材」

「洗練されたデザイン」

これら三要素を融合し、皆様に

「履きやすい」と喜んで頂ける靴を

日々開発しております。

オリジナルシューズブランド”YOSHITO”を

製造・販売するシューズメーカーです。

「こだわりの製法」

「厳選した素材」

「洗練されたデザイン」

これら三要素を融合し、皆様に

「履きやすい」と喜んで頂ける靴を

日々開発しております。

ニューロンドンの歴史

History of New London

ニューロンドンの歴史

Start of New London

ニューロンドンの始まり

株式会社ニューロンドンの靴メーカーとしての歴史は

1952年、聖心女子学院をはじめとする学校や

百貨店・病院の看護師用などの

制服靴の製造から出発しました。

それは、一人ひとりの足の寸法を測ることから始める

まさにオーダーメイドとも呼べる靴づくりでした。

創業当時から変わらず

「快適な履きやすさ」を追求

「日本人の足を考えた木型と手づくりにこだわり、

履きやすさを第一に考えた靴をお届けする」という

創業当時から変わらぬ姿勢を貫きながら、

常に製靴技術の向上に努めています。

その成果を示す一環として、

1973年にはG.D.S.(ドイツ靴見本市)にも出品。

イタリアの雑誌などに取り上げられるなどの

高い評価を得ることができ、ドイツを中心に

ヨーロッパでの販売活動を行ってきました。

1998年、長年の理想をカタチにした

オリジナルブランド「YOSHITO」を発表。

快適な履きやすさ・歩きやすさを実現するために

90年代の初めにイタリアのボローニャの靴メーカーより

修得した"ボロネーゼ製法"や"プラット製法"

といった技術を採用。

「履き心地のよさ」「デザイン」「素材」の

三要素のバランスを融合し

都会的感覚を持つキャリア女性をターゲットに

スタイリッシュなコーディネーションで

今の女性らしさを表現するブランドとして

多くのお客様から支持を得ています。

会社理念

Company philosophy

『履きやすさ』へのこだわり

足を包み込む製法

Manufacturing method

足を包みこむ製法へのこだわり

ボロネーゼ製法

[ボロネーゼ製法]

イタリア・ボローニャ地方発祥の製法で、

靴の前半分を袋状に縫い合わせて

クッション素材を入れています。

足を包み込むような履き心地と

ソールの返りのよさが特徴です。

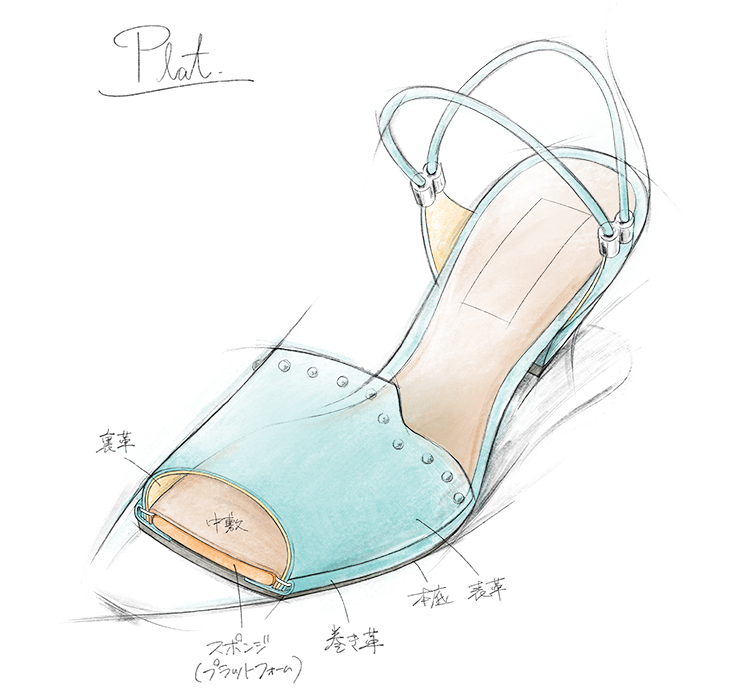

プラット製法

[プラット製法]

アッパーと中敷、巻き革を縫い合わせて

袋状にしたものにクッション素材を

入れて靴の土台に巻き込む製法です。

靴全体がひとつの袋状になっているため、

ソフトで軽い履き心地が得られます。

〈YOSHITO〉では、主にサンダルと

カジュアルな靴に採用しています。

素材のこだわり

Quality

素材へのこだわり

足当たりが柔らかな

カーフ(仔牛)・キッド(仔山羊)・ラム(仔羊)の革を、

イタリアを中心に世界中から

上質な素材を集めて使用しています。

この素材のこだわりによって

〈YOSHITO〉の靴は履きこむほどに

足になじんでいき、あなたの足にフィットします。

職人技の継承

Inherting Craftsmanship

職人技術の継承

2004年には100%独資の子会社をベトナムに設立。

職人の高齢化に伴い、後継者の育成を図るために

ベトナムで技術や技能の継承を始めました。

すべての革や材料をイタリア、日本などから送り

品質第一をモットーに、丁寧な靴づくりを行っております。

より品質の高い靴を作るために

革の裁断から縫製・底付け・仕上げ

検品・X線検査全ての工程を一貫生産し、

日々品質向上に励んでおります。

YOSHITO Dealers

YOSHITO Dealers

ヨシトお取り扱い店舗について

Social Networking Service

YOSHITOでは、Instagramを中心にSNSでも

商品の情報を発信しております。

ぜひこの機会にご覧下さいませ。

→ go to yoshito_shoes